Pulse Single Mode Laser Cleaning Machine

Pulse single mode

Description:

High single-pulse energy with high peak power, ideal for cleaning thick surface contamination layers,

requiring deep cleaning and thorough surface treatment.

Applications:

- Industrial Rust Removal:

Uses a high-peak power laser to instantly sublimate rust, exposing the metal surface. This prevents secondary oxidation, avoiding the

formation of black iron oxide (Fe₃O₄) after removing the yellow iron oxide (Fe₂O₃).

- Oil and Grease Removal:

Instantly heats the surface, vaporizing oils and grease while preserving the base material.

- Outdoor Building Surface Cleaning:

Cleans corrosion caused by acid rain, effectively removing surface coatings, oxides, stains, and dust, restoring the building's original

appearance.

- Paint Removal:

Removes all coatings from the substrate in one pass or selectively layer by layer. Suitable for ships, bridges, transmission towers,

and aerospace parts.

- Metal Welding and Coating Preparation:

Cleans metal surfaces before welding or coating, removing oxides, grease, oil stains, chlorides, and other residues.

Post-welding, it removes oxides and heat-affected zones, improving appearance and corrosion resistance.

- Cultural Relics Cleaning:

Gently cleans sandstone, marble, granite, terracotta, and concrete without causing damage.

The laser can be precisely adjusted for delicate cleaning of stained or aged surfaces.

| Model | CZ-QD70 | CZ-QD100 | CZ-QD200 | CZ-QD300 | CZ-QD500 | CZ-QD1000 |

| Laser power (W) | 70W | 100W | 200W | 300W | 500W | 1000W |

| Power adjustment range | 10-100% Adjustable | |||||

| Power wavelength (nm) | 1070 ± 10 | |||||

| Working distance (mm) | 160~300 ± 20mm (select as needed) | |||||

| Maximum power consumption (KWH) | 800 | 1000 | 2000 | 2500 | 3500 | 5000 |

| Gun head weight (kg) | 4.5kg | |||||

| Maximum monopulse MJ | 1.2 | 1.2 | 1.5 | 5 | 50 | 50 |

- Contact Information

Email: sales@xzlasers.com

WhatsApp: +8617702282583

- Flexible Payment Options

We offer secure and easy payment methods:

Letter of Credit (L/C): Ideal for large orders, ensuring secure transactions.

Telegraphic Transfer (T/T): Fast and reliable, with 30% upfront and the balance before shipment.

PayPal/Western Union: Fast payment for small or first-time orders.

- Various Delivery Methods

We offer delivery options to suit your needs:

Shipping: Best for bulk orders, delivery within 15-30 business days.

Air Freight: Quick delivery for urgent orders.

- Delivery Time

Domestic Orders: Ships within 2-5 business days after payment.

International Orders: Delivery time varies by destination, typically 10-30 business days.

- Shipping Costs

Shipping costs depend on weight and destination. We’ll provide a detailed quote when confirming your order.

- Contact Information

Email: sales@xzlasers.com

WhatsApp: +8617702282583

- Warranty Period:

Continuous Laser Cleaning Machine: 1 year for the entire machine, 1.5 years for the laser device (lens is not covered under warranty).

Pulse Laser Cleaning Machine: 1 year for the entire machine, 1.5 years for the laser device (lens is not covered under warranty).

Warranty Period | Entire Machine | Laser Device | Lens Coverage |

Continuous Laser Cleaning Machine | 1 year | 1.5 years | Not covered |

Pulse Laser Cleaning Machine | 1 year | 1.5 years | Not covered |

- Warranty Terms:

During the warranty period, if any failure occurs due to non-human reasons, the faulty parts will be replaced after technical confirmation.

Our company will send new parts to the customer free of charge (laser source will be charged separately).

For laser sources and cleaning/welding guns, the faulty parts must be returned first. Other parts do not need to be returned.

- Other Terms:

In case of complete machine damage, the customer needs to provide clear photos or videos of the machine and packaging. Our technical team will confirm the issue and arrange for a secondary delivery if necessary. The customer should also contact the shipping company to make insurance claims.

- Contact Information

Email: sales@xzlasers.com

WhatsApp: +8617702282583

- Laser Charging Instructions:

Time Period | Laser Source Replacement Cost | Shipping Fee |

Within 1.5 year | Free replacement | Both parties pay |

After 1.5 years | At the customer's expense. | Customer pays |

1. What is the working principle of the laser cleaning machine?

The laser cleaning machine uses a high-energy laser beam to irradiate the surface of an object, instantly evaporating or stripping surface contaminants such as rust, grease, oxide layers, and coatings without damaging the substrate.

2. What materials can the laser cleaning machine clean?

Laser cleaning machines are suitable for cleaning:

Metals (steel, aluminum, copper, stainless steel, etc.)

Stone (marble, granite)

Concrete

Glass

Other surfaces

3. What are the common applications of the laser cleaning machine?

Rust and paint removal from metal surfaces

Removal of oxide layers before and after welding

Mold surface cleaning

Cleaning of stone sculptures and building surfaces

Cleaning of precision parts

4. How to choose the right laser cleaning machine?

We offer three types of laser cleaning machines for different applications:

Continuous Laser Cleaning Machine: Suitable for large metal surface rust removal and thick coating removal. High power and fast cleaning speed.

Single-Mode Pulsed Laser Cleaning Machine: Suitable for removing thin layers of contaminants, with high cleaning precision and minimal damage.

Multi-Mode Pulsed Laser Cleaning Machine: Suitable for cleaning precision parts and ultra-precision cleaning (such as cultural relic restoration, mirror glass surfaces), offering more delicate cleaning for sensitive surfaces.

5. How to choose the power of the laser cleaning machine?

Continuous Cleaning Machine: Power is usually between 1500W - 3000W, suitable for large area and high-efficiency cleaning.

Pulsed Cleaning Machine: Power is usually between 50W - 1000W, suitable for precision and sensitive surface cleaning.

High-Power Cleaning (Above 3000W): For safety reasons, automatic fixtures are recommended.

6. What is the cleaning speed of the laser cleaning machine?

The cleaning speed can reach 10-20㎡/hour.

The exact speed depends on the material and the thickness of the contamination layer.

7. Will the laser cleaning machine damage the substrate?

Almost no damage. Laser cleaning is a non-contact cleaning method. The laser parameters (power, frequency, pulse width) can be precisely adjusted to ensure that only contaminants are removed without damaging the substrate.

8. Are all laser cleaning machines handheld?

Mostly, they are handheld, which makes them flexible and portable for on-site operations. Customization is available upon request.

9. Is the laser cleaning machine easy to operate?

Yes, our laser cleaning machines are equipped with a touchscreen control system, which is simple and intuitive, with multilingual interface options.

10. Can the laser cleaning machine operate continuously?

Yes, our laser cleaning machines are designed for 24-hour continuous operation, offering stable performance and long service life.

11. Is laser cleaning harmful to humans?

Laser cleaning is safe, but protective glasses must be worn to avoid direct laser exposure to the eyes. It must be operated under safe conditions.

12. Does the laser cleaning machine require consumables?

No, the laser cleaning machine does not require consumables, chemicals, or abrasives, resulting in low maintenance costs.

13. Is the maintenance of the laser cleaning machine complicated?

Maintenance is simple, requiring only regular cleaning of optical lenses and the cooling system to ensure normal operation.

14. Does the machine come with installation training?

Yes, installation is straightforward. We provide a detailed installation manual and remote video guidance.

15. What is the warranty period for the equipment?

We provide a warranty of at least 12 months, offering free repairs during the warranty period and lifetime technical support.

16. What are the prohibitions for using a laser cleaning machine?

Laser cleaning machines are prohibited in environments where open flames are restricted (such as flammable and explosive areas).

- Contact Information

Email: sales@xzlasers.com

WhatsApp: +8617702282583

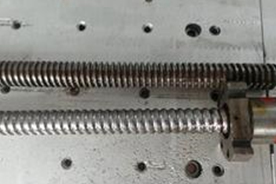

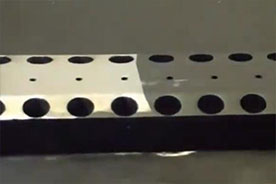

Sample Display